Laser Etching Versus Laser Engraving

Laser Etching versus Laser Engraving

How can you make money with a laser?

Business owners often choose lasers over other technologies because of their broad system capabilities. Using the two most common laser types -- CO2 and fiber -- you can laser etch, engrave, cut, or mark almost anything.

CO2 lasers can cut and engrave the widest range of materials, such as plastics, wood, paper, fabric, acrylic, rubber and cardboard. The CO2 laser can also engrave on glass, ceramic, stone, and coated metals such as anodized aluminum or coated metals. It works by vaporizing the material, leaving an indentation or cut into the material. A fiber laser basically does what a CO2 laser cannot. The fiber laser is used for marking or engraving bare metals and marking plastics. Fiber lasers are optimally suited for metal marking methods such as annealing and metal engraving, and for making high-contrast markings on plastics. Discover how lasers work

Learn how laser etching, engraving, and cutting differ and when to use them

In addition to the broad range of materials that you can work with on a laser machine, there are a few different ways you can process materials:

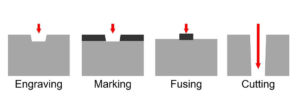

Engraving

Laser engraving works by vaporizing some of the base material with cone shape indentation. (Engraving depth capabilities depend on your specific laser.) Examples of materials well-suited for laser engraving include wood, leather, rubber, and acrylic, to name a few.

Etching or Marking

During the process of laser etching, the cover layer of your material is vaporized, producing little to no depth but usually high contrast marking. The process is like cutting, except only the top layer is vaporized. Laser etching works well on materials with two or more layers, coated metals, anodized aluminum and engravers plastics.

Cutting

Laser cutting happens when you apply enough power at a low enough speed to completely vaporize material all the way through. If a material is flammable, in most cases it can be cut by a laser.

Fusing

Fusing means adding a layer with ceramic powders onto the surface of metals, ceramics or glass, producing a fusing of the materials to add contrast. This process is accomplished using materials such as Thermark, Cermark or Laserbond.