Digitally printed puzzle

Preparation

Required materials:

- 1/2 sheet TroLase Metallic, matte brushed Aluminum/Black 1.6 mm

- 1/2 sheet TroLase ADA Polar White 1.6 mm

- Photo Frame 30 x 40 mm

- Paper or other lightweight material to cover the working table

Machine used:

- Speedy 400, 120 Watt

- 2″ lens

- vacuum table

- acrylic cutting grid

Downloads:

Tips: Check the internet for free software you can download and use to make the puzzle pieces.

Step 1: Create print and laser design

Download our graphic or create your own design. Tips and tricks on how to create graphics for Digital Print Series can be found here.

Then send the puzzle engrave-and-cut file to the laser.

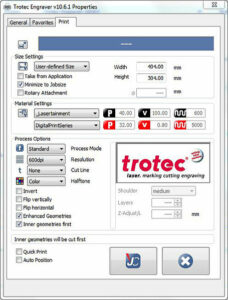

Print settings

Process mode: Standard / Resolution: 600dpi / Cut line: none Halftone: Color / Others: Optimized geometries, inner geometries first

Step 2: Laser process puzzle

We used the quality-optimized TroLase standard parameters from JobControl® for the engraving settings. Due to the complex geometries of the puzzle pieces, we adapted the cutting parameters. (The parameters might vary depending on the machine used and the available laser power.)

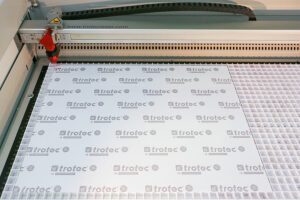

Next put the printed sheet of Digital Print Series on the acrylic cutting grid of your Trotec Laser. Engrave and cut the design.

Important: Engrave from bottom to top. This prevents the dust from collecting in the engraved areas. Take a sheet of paper and put it underneath the cut puzzle so that you can remove all elements from the laser at once.

| Color | Process | Power(%) | Speed (%) | ppi/Hz |

|---|---|---|---|---|

| Black | Engrave CO2 | 40 | 100 | 600 |

| Red | Cut CO2 | 32 | 0.8 | 5000 |

| Blue | Cut CO2 | 60 | 1.62 | 5000 |

Step 3: Graphic base plate

The base plate is necessary to display the puzzle in a frame. Send the graphic to the laser using the settings below.

Process mode: Standard / Resolution: 1000 dpi / Cut line: none / Halftone: Color / Others: –

Step 4: Laser process base plate

The step is to put the TroLase ADA on the acrylic cutting grid and cut it out.

Laser parameters:

Color: Red / Process: Cut CO2 / Power: 65% / Speed: 2% / 1000ppi

Tips: We used the speed-optimized standard laser parameters for TroLase ADA in JobControl®.

Step 5: Cleaning and assembly

After engraving, clean the puzzle using a damp cloth.

Tips: f you leave the material in the laser with the vacuum activated after you are finished processing, the parts will stay in position during cleaning.

Inspiration

- Make a bigger base plate and use the new Trotec signage mounting devices to mount the puzzle on the wall. In this case, you could put double-sided adhesive tape on the printed plate before cutting.

- Print general atmospheric pictures (e.g. sunsets, sandy beaches, flowers,…) on stock and engrave them afterward according to your customers’ requirements.